With the development and application of technology, especially the rapid development of intelligent technologies such as touch screens, Internet of Things and cloud computing in recent years, whether it is the “Industry 4.0” proposed by the German Union Government in the “High-Tech Strategy 2020” plan , or the concept of “Smart Factory 1.0” proposed by China Science and Technology Automation Alliance, both aim to use emerging technologies to promote industrial intelligence, so as to build a humanized chemical factory with high efficiency, energy saving, green environmental protection and comfortable environment. “Intelligent” technology covers a wide range of content, and there are many companies committed to intelligent technology. Among them, Guangzhou Maker-ray Intelligent Technology Co., Ltd. stands out in this industry.

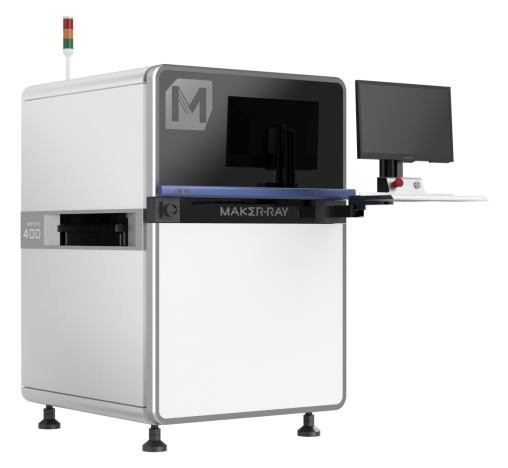

Guangzhou Maker-ray Intelligent Technology Co., Ltd. is a subsidiary of CVTE. It It is an electronic product R&D and testing service provider. With machine optical and deep learning algorithms as the core, it provides customers with various optical inspection solutions. , is a high-tech enterprise dedicated to creating high-end flexible and intelligent testing equipment.

With the wave of industrial intelligence, the electronics manufacturing industry has ushered in new opportunities for upgrading, but it also faces many challenges. In the traditional production process, PCBA inspection relies on manpower, which not only requires high requirements for operators, but also does not have uniform standards for manual operation. In addition, there are many disadvantages such as the inability to trace the production situation in time, and the inability of data to be informatized. In order to meet the needs of the times, Maker-ray Technology has launched AIS430 3D AOI equipment.

AIS430 is based on big data training and adopts convolutional neural network algorithm, which not only realizes fast programming, but also has the ability to grow the equipment, solving the pain points of long programming time and high learning cost of traditional algorithms in the industry. In addition to the innovation on the algorithm side, AIS430 applies high-speed, high-resolution image processing technology to efficiently integrate height information in multiple directions, greatly enhancing 2D detection performance and 3D imaging speed.

In addition, it supports 3D projection imaging based on 4/8 directions at the same time, efficiently fuses multi-directional height information, and minimizes shadow problems. AIS430 can also intelligently identify and search, search for trained components with one click, quickly query production statistical reports-SPC, remotely view tracking data, the programming is simple and easy to learn, and people can easily master intelligent programming, which greatly reduces the learning and use costs of customers to control the quality of product production efficiently.

In recent years, the pace of intelligent transformation of the industrial Internet has accelerated, and vertical segments of industrial manufacturing such as AOI equipment will also usher in a broad space for development. Maker-ray Technology AIS430 3D AOI equipment helps intelligent manufacturing!