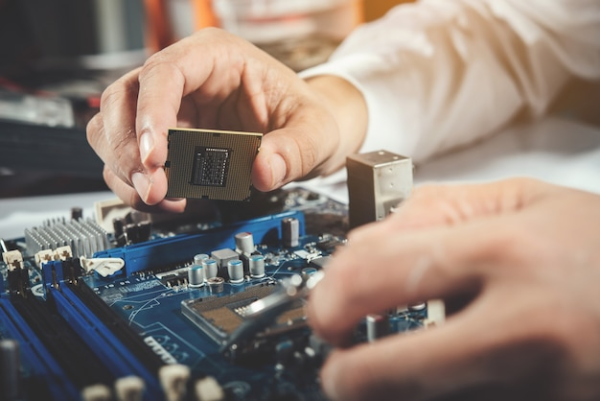

In the fast-paced world of PCB manufacturing, quality control is a top priority. Every printed circuit board must meet stringent standards to ensure product reliability and customer satisfaction. However, traditional manual inspection methods have their limitations. They are time-consuming, prone to human error, and lack the required level of accuracy. This is where Maker-ray‘s AOI machine for pcb comes in, revolutionizing PCB quality control.

Introducing Maker-ray‘s Advanced AOI Machine for PCB Inspection

Maker-ray, a leading brand in the industry, offers an advanced AOI machine for PCB inspection. Leveraging cutting-edge imaging technologies and intelligent algorithms, Maker-ray’s AOI machine thoroughly analyzes each circuit board, leaving no room for undetected defects. By automating the inspection process, it eliminates human error and significantly reduces the time required for quality control.

Advantages of Maker-ray‘s AOI Machine for PCB Inspection

- Superior Defect Detection: Maker-ray’s AOI machine for PCB inspection provides unparalleled precision and accuracy. Its high-resolution imaging system captures detailed images of each PCB, enabling precise defect detection. The advanced AI-driven algorithms analyze these images, quickly identifying flaws and anomalies. Whether it’s component misalignments, soldering issues, or surface irregularities, Maker-ray’s AOI machine has got it covered.

- Customizable and User-Friendly: Maker-ray’s AOI machine incorporates AI-driven algorithms and intuitive programming options. Manufacturers can easily set up inspection parameters and customize the machine according to their specific requirements. The user-friendly interface streamlines the programming process, saving valuable time and increasing productivity.

- Deep Learning and OCR Recognition: Maker-ray’s AOI machine integrates deep learning and OCR recognition technologies. This enhances its performance by accurately recognizing and analyzing various PCB components and markings. The combination of deep learning and OCR recognition ensures thorough and precise inspection results.

Revolutionizing PCB Quality Control with Maker-ray

By choosing Maker-ray’s AOI machine for PCB inspection, manufacturers can optimize their quality control processes and deliver high-quality PCBs. The advanced technologies and unmatched precision offered by Maker-ray’s AOI machine enable enhanced defect detection, streamlined workflows, and increased customer satisfaction. Stay ahead of the competition with Maker-ray’s AOI machine for PCB and ensure the reliability and efficiency of your inspection processes.

Conclusion

In conclusion, Maker-ray’s advanced AOI machine for PCB inspection is a game-changer in the world of PCB manufacturing. By leveraging Maker-ray’s AOI machine, manufacturers can ensure that every printed circuit board meets the highest standards of quality. Its superior defect detection capabilities, including the identification of component misalignments, soldering issues, and surface irregularities, guarantee the production of flawless PCBs. The machine’s deep learning and OCR recognition technologies further enhance its performance, enabling accurate analysis of various PCB components and markings.Choosing Maker-ray’s AOI machine for PCB inspection translates into streamlined workflows, increased productivity, and ultimately, customer satisfaction.