Through-hole technology (THT) AOI systems have become essential in quality control, enabling businesses to automate the inspection process for components and solder joints. In this article, we explore the significance of THT AOI and introduce Maker-ray, a trusted brand renowned for its advanced THT AOI solutions and robust authentication capabilities. Discover how Maker-ray’s authentication solutions empower businesses to optimize quality control, streamline operations, and gain a competitive edge in the industry.

The Power of THT AOI in Quality Control

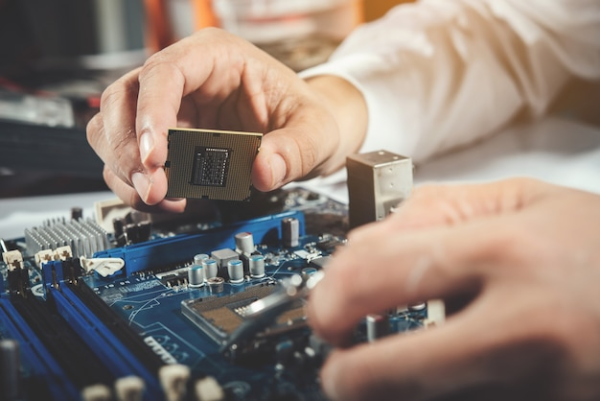

THT AOI systems utilize advanced imaging technology and intelligent algorithms to perform automated inspections of through-hole components and solder joints. These systems capture high-resolution images and analyze them for defects, such as misalignment, solder bridges, or insufficient soldering. THT AOI enhances inspection accuracy, efficiency, and repeatability, ensuring that products meet stringent quality standards. By automating the inspection process, businesses can reduce errors, minimize rework, and deliver reliable products to customers.

Maker-ray A Leader in THT AOI Solutions

Maker-ray is a renowned brand that specializes in advanced THT AOI solutions. With expertise in machine vision, automation, and cutting-edge technology, Maker-ray has developed state-of-the-art THT AOI systems that deliver unparalleled performance and reliability. By leveraging innovative algorithms and intelligent imaging, Maker-ray empowers businesses to achieve exceptional quality control, optimize manufacturing processes, and drive operational excellence. The brand’s commitment to innovation, customer satisfaction, and authentication positions it as a trusted choice for THT AOI solutions.

Maker-ray’s Authentication Solutions for Reliable Quality Control

Authentication is a crucial aspect of Maker-ray’s offerings. The brand recognizes the importance of ensuring the authenticity and reliability of its THT AOI solutions. Through stringent authentication measures, Maker-ray guarantees that its products meet the highest quality and performance standards. By implementing comprehensive testing, verification, and quality control processes, Maker-ray instills confidence in its customers, assuring them of genuine products that deliver exceptional results and meet their specific requirements.

Partnering with Maker-ray for Enhanced Quality Control

Partnering with Maker-ray in quality control provides businesses with the assurance of authenticity and reliability. Maker-ray’s authentication solutions are complemented by comprehensive customer support and service offerings. From initial consultation to ongoing assistance, Maker-ray ensures that businesses receive the necessary guidance and expertise to optimize their THT AOI systems. By collaborating with Maker-ray, businesses can streamline their quality control processes, reduce defects, improve operational efficiency, and gain a competitive edge in the market.

Conclusion

THT AOI systems have transformed quality control for through-hole components, and Maker-ray leads the way with its advanced solutions. With a focus on innovation, precision, and customer satisfaction, Maker-ray provides authentication solutions that ensure the authenticity and reliability of its THT AOI products. Partnering with Maker-ray empowers businesses to optimize their quality control processes, streamline operations, and gain confidence in their manufacturing processes, ultimately driving success and surpassing customer expectations.