In the realm of electronics manufacturing, ensuring the highest standards of quality control is paramount. Automated Optical Inspection (AOI) machines have emerged as indispensable tools for inspecting Printed Circuit Boards (pcbs) with speed and precision. In this article, we explore the significance of AOI machines for pcb quality control and introduce Maker-ray, a leading provider in this field. We will also highlight the value of Maker-ray’s Field Application Engineer (FAE) service and training, empowering businesses to optimize the performance of their AOI machines.

The Power of AOI Machines in PCB Quality Control

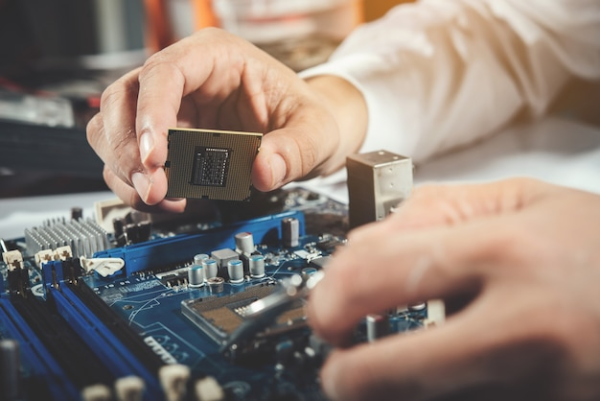

AOI machines have revolutionized pcb quality control by leveraging advanced imaging technology and intelligent algorithms. These machines scan pcbs to detect defects such as missing components, misalignment, solder joint issues, and incorrect polarity. With high speed and accuracy, AOI machines provide real-time feedback, enabling manufacturers to identify and rectify issues early in the production process. This reduces the risk of faulty pcbs reaching the market, enhances product reliability, and streamlines manufacturing operations.

Maker-ray Elevating AOI Solutions

Maker-ray is a trusted provider specializing in advanced AOI machines that redefine pcb quality control in the electronics manufacturing industry. With expertise in machine vision and automation technology, Maker-ray has developed cutting-edge solutions that deliver exceptional accuracy and reliability. The brand’s commitment to innovation, quality, and customer satisfaction has solidified its position as a preferred choice for state-of-the-art AOI machines. Maker-ray empowers businesses to achieve superior quality control, optimize production processes, and drive operational excellence.

Leveraging Maker-ray’s FAE Service and Training for Optimum Performance

To help businesses optimize the performance of their AOI machines, Maker-ray offers a comprehensive Field Application Engineer (FAE) service and training program. The FAE service provides expert guidance and support throughout the integration and implementation of Maker-ray’s AOI machines. Maker-ray’s skilled Field Application Engineers possess extensive knowledge of the technology and can provide tailored solutions to meet specific customer requirements. We work closely with clients to ensure seamless system integration, optimize performance, and address any challenges that may arise.

In addition to the FAE service, Maker-ray’s training program equips businesses with the necessary skills and proficiency to operate and maintain AOI machines effectively. Through hands-on training sessions, interactive workshops, and educational resources, employees gain in-depth knowledge of the machines’ operation, programming, and maintenance. This knowledge transfer not only enhances operational efficiency but also empowers businesses to drive continuous improvement in pcb quality control practices.