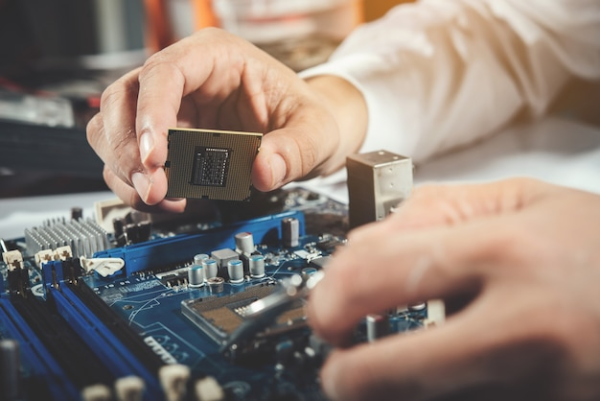

Efficiency and quality control are crucial in the quick-paced electronics manufacturing sector. Consider incorporating Maker-ray‘s SMT AOI equipment to speed up production and guarantee faultless goods. Manufacturers can quickly and accurately test printed circuit boards (PCBs) and electrical components thanks to these cutting-edge tools. You may greatly increase productivity, lower errors, and streamline production for your company by integrating SMT AOI machine into your manufacturing operations.

Understanding the Importance of Quality Inspection in SMT Assembly

SMT assembly involves intricate processes, and even minor defects can lead to major issues down the line. To identify and rectify defects early in the manufacturing process, quality inspection is essential. Maker-ray offers advanced SMT AOI machines that provide comprehensive inspections, ensuring that your PCBs and components meet the most stringent quality standards before proceeding further in production.

Benefits of Integrating SMT AOI Machines in Manufacturing Processes

Integrating SMT AOI machines into your manufacturing processes offers numerous advantages. Firstly, these machines provide high-speed inspections, significantly reducing the time required for manual inspections. This leads to faster production cycles and increased throughput. Secondly, SMT AOI machines offer improved accuracy compared to manual inspections, minimizing the chances of overlooking defects. Lastly, these machines seamlessly integrate with smart manufacturing systems, allowing for real-time data analysis and process optimization.

Overcoming Obstacles in Current Inspection Techniques

Traditional inspection methods in electronics manufacturing, such as manual visual inspections, are time-consuming and prone to human error. The complexity of PCBs and the miniaturization of components further exacerbate these challenges. Maker-ray’s SMT AOI machines address these issues by automating the inspection process. With advanced imaging technology, sophisticated algorithms, and machine learning capabilities, our machines can accurately and efficiently detect defects.

Maker-ray: The Leader in SMT AOI Technology

When it comes to SMT AOI technology, Maker-ray is a renowned leader known for its expertise and industry leadership. Understanding the challenges faced by manufacturers, Maker-ray has developed cutting-edge advancements in SMT AOI technology. Our machines combine state-of-the-art hardware and software solutions to deliver exceptional inspection capabilities, enabling manufacturers to achieve unmatched levels of quality and efficiency.

Advantages and Special Features of Maker-ray‘s SMT AOI Machines

Maker-ray’s SMT AOI machines offer a range of unique features and advantages. Firstly, we provide high-speed inspections, allowing manufacturers to meet demanding production requirements without compromising quality. Our machines also boast improved accuracy, ensuring that even the tiniest defects are detected, thereby safeguarding your brand reputation by reducing the likelihood of faulty products reaching customers. Furthermore, Maker-ray’s SMT AOI machines seamlessly integrate with smart manufacturing systems, enabling real-time data analysis and facilitating continuous process optimization.

Conclusion

In conclusion, SMT AOI machines are indispensable for optimizing manufacturing efficiency in the electronics industry. With Maker-ray’s advanced SMT AOI technology, you can revolutionize your inspection process and enjoy numerous benefits such as high-speed inspections, improved accuracy, and integration with smart manufacturing systems. By incorporating Maker-ray’s SMT AOI machines into your operations, you can streamline your processes, minimize errors, and achieve higher levels of efficiency and quality. Take advantage of Maker-ray’s expertise and industry-leading solutions to stay ahead in the competitive electronics manufacturing landscape.