How Can AI Improve AOI Inspection?

Automated Optical Inspection (AOI) refers to the automated visual inspection of PCBs and other electrical circuits where a camera scans the device for both quality defects and catastrophic failures. This non-contact test method is highly accurate and much faster than manual inspection. AOI inspection is used in a wide variety of applications in various industries, including PCBs, fingerprint matching, biomedical science, batter products, food packaging, medical packaging, machinery, automotive, and more.

AOI Overview

AOI inspection is a key technique used in the testing and manufacture of PCBs. It enables accurate and fast inspection of electronic assemblies to ensure that the final quality of products is high and up to customers’ expectations.

- Operating Principle

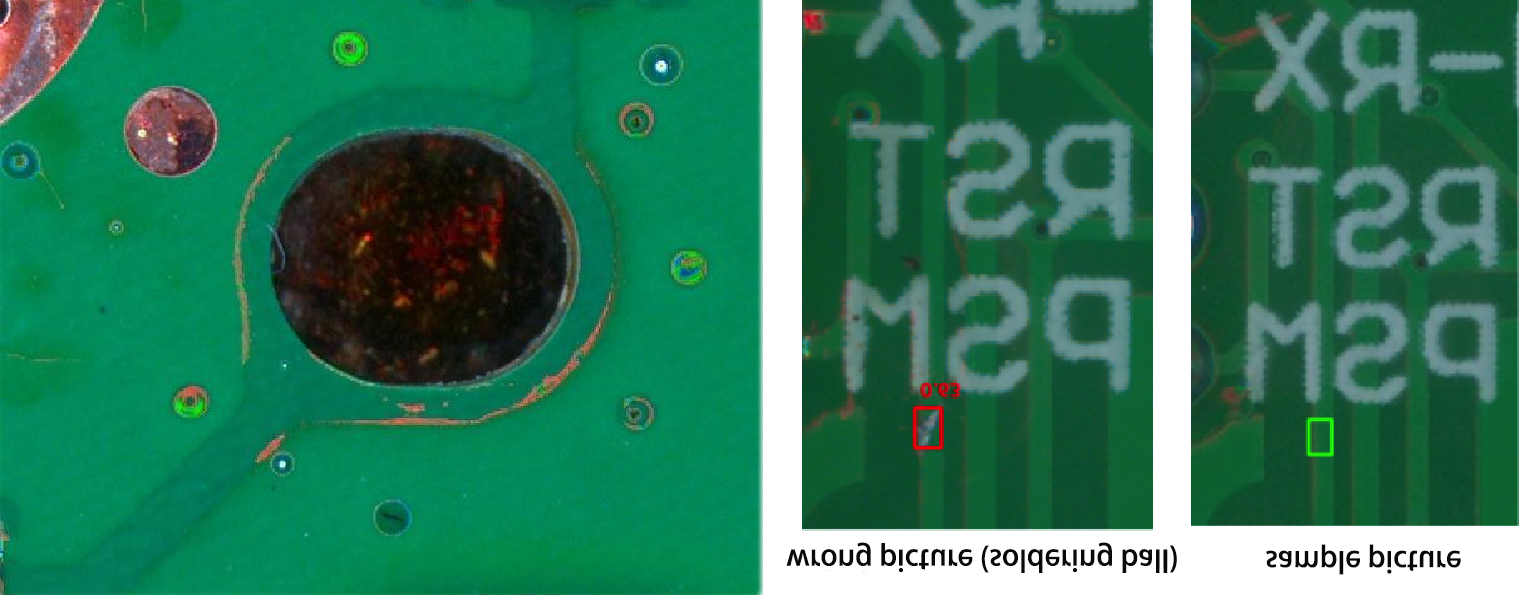

AOI uses advanced algorithms and optics to inspect PCBs for defects. Its operating principle is based on using high definition camera and lighting system to obtain images featuring different wavelengths. The images are then compared with the ones stored in the database, and if any defects are detected, the signal is analyzed and the issue is flagged. The analysis is performed by intelligent processing software that is built within the automated optical inspection system.

- Critical Advantages

As compared to manual inspection, AOI inspection has many critical advantages. Modern circuit boards are becoming more and more complex, which means that manual visual inspection is not always a viable option. This is where AOI inspection becomes invaluable. It offers the following advantages:

- Accurate detection of visual defects

- Customizability and flexibility

- Timely feedback on production defects

- Reliable and cost-effective

- Fast speed and high stability

Future Development – Incorporated with AI

AOI inspection systems are widely used for quality control in PCB production. But since circuit boards are becoming more complex, there is a need for more advanced solutions. By incorporating AI with automated optical inspection, the capabilities of the system can be significantly enhanced to achieve better accuracy, faster speed, and to minimize false calls. Many manufacturers are switching to these innovative approaches. The AI-powered AOI inspection market is expected to grow in the future.

What Does the AI Bring to AOI?

AOI inspection is quite successful, but there is room for improvement. The incorporation of AI brings the flexibility of AOI to new heights. The perks of this integration are as follows:

- Easy to Operate

AI-powered AOI inspection systems reduce operational budgets, improve workshops, and boost productivity. The level of automation supported by AI is also very time-saving. These systems have a user-friendly interface that makes work much easier for human employees. Setting up and running the inspection system is hassle-free.

- High Accuracy

In the modern manufacturing process, circuit boards need to be inspected at different stages to facilitate the early detection of defects. To increase the accuracy and speed of the AOI inspection, the use of AI has become indispensable. It increases accuracy and process time, particularly with the multi-station inspection.

Maker-ray Offers AI-Powered AOI Products

Maker-ray is a global provider of intelligent optical inspection products. Our non-contact inspection systems are suitable to be used in all areas of production across a wide range of sectors. With our reliable solutions, we aim to make the PCB production process faster, more flexible, and more efficient.

Our products at Maker-ray cover various fields, including SPI 3D, SMT 2D/3D AOI, Coating AOI, THT AOI /final inspection, Semiconductor (MLED) Inspection, and more. All of our products are backed by our commitment to quality. These top-quality, innovative solutions are used all over the world in automated production processes for defect detection, guidance, inspection, and quality control in many industries.

Conclusion

Automated optical inspection is an extremely useful technique for reducing potential defects in PCB manufacturing. By leveraging AI-powered AOI inspection, manufacturers can ensure timely defect detection and provide more efficient, cost-effective, and faster production of circuit boards. Investing in a reliable AOI inspection product is crucial to ensure optimal results. Maker-ray offers many products in this category.

A trusted Guangzhou brand, Maker-ray is committed to ensuring that all the products offered feature advanced technologies and the highest possible standard. Our certified AI-powered AOI inspection products consistently meet quality standards. This combined with our attention to detail, after-sale service, and commitment to quality makes us one of the leading intelligent automated optical inspection solutions providers in the industry. For more information about our company and products, feel free to contact us.