Automotive

High-precision Imaging.

True Restoration of Defect Details

True Restoration of Defect Details

Industry pain points

Miniature Components & Strict Production Process Requirements.

Traditional AOI inspection is difficult to be compatible with different heights and sizes of the components.

The imaging is inaccurate with traditional AOI light sources. It will cause high false calls for thin and long pins.

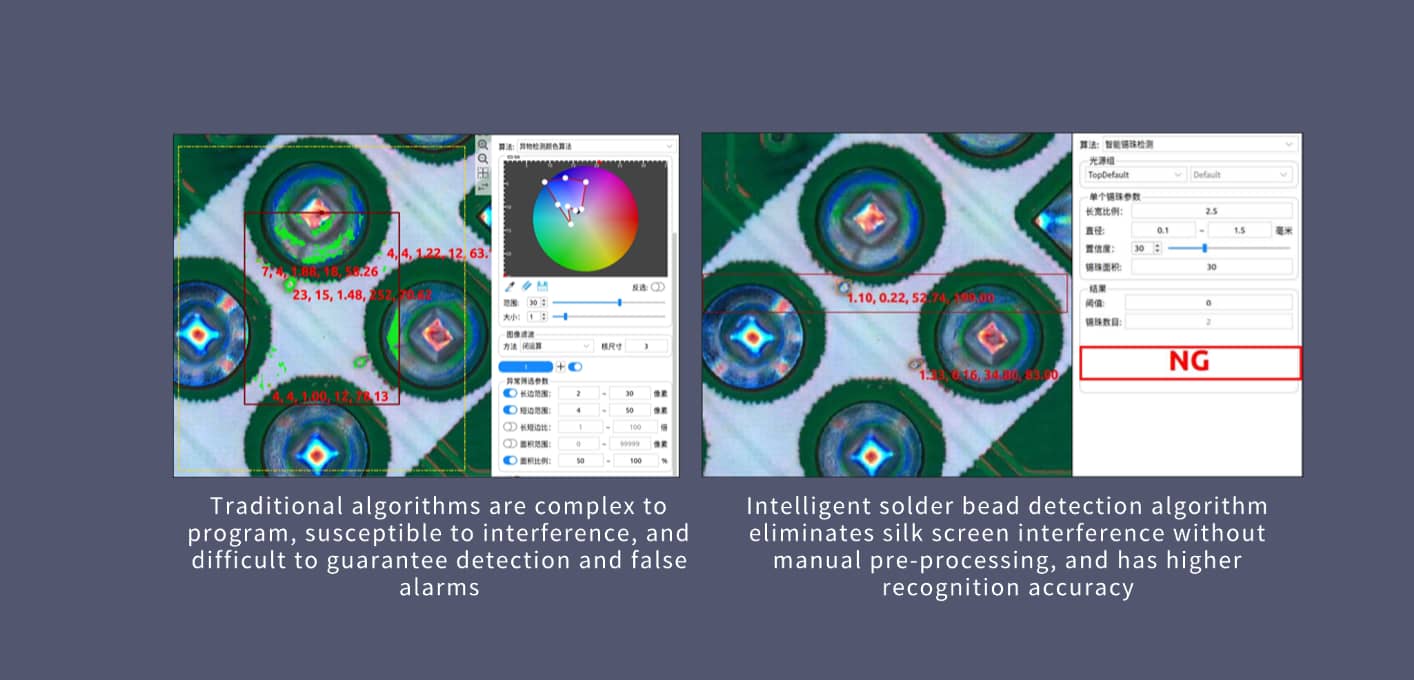

Traditional algorithm programming is complex, susceptible to interference, and difficult to guarantee accuracy.

Solution

High-resolution Imaging. True Restoration of Defect Details.

3D AOI

01

High-resolution imaging

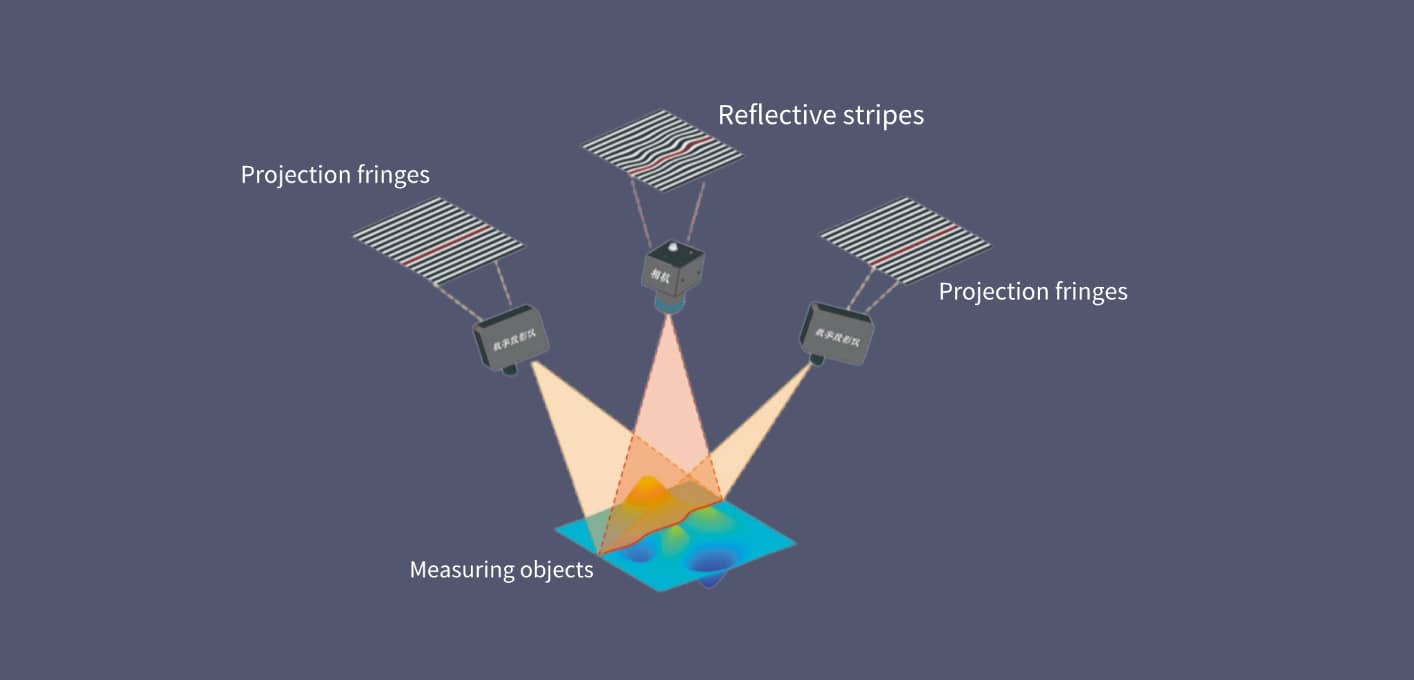

Multi-angle projection and multi-frequency fringe structured light fusion solve the problem of imaging overexposure.

02

AI programming

AI coverage rate is up to 95%, which can comply with intelligent searching, identify components, and automatically generate a detection box.

03

Stable and reliable Inspection

A laser interferometer calibrates equipment accuracy to ensure each machine's consistency and repeated accuracy.

Solution Advantages

Provide more reliable safety protection for automotive electronics.

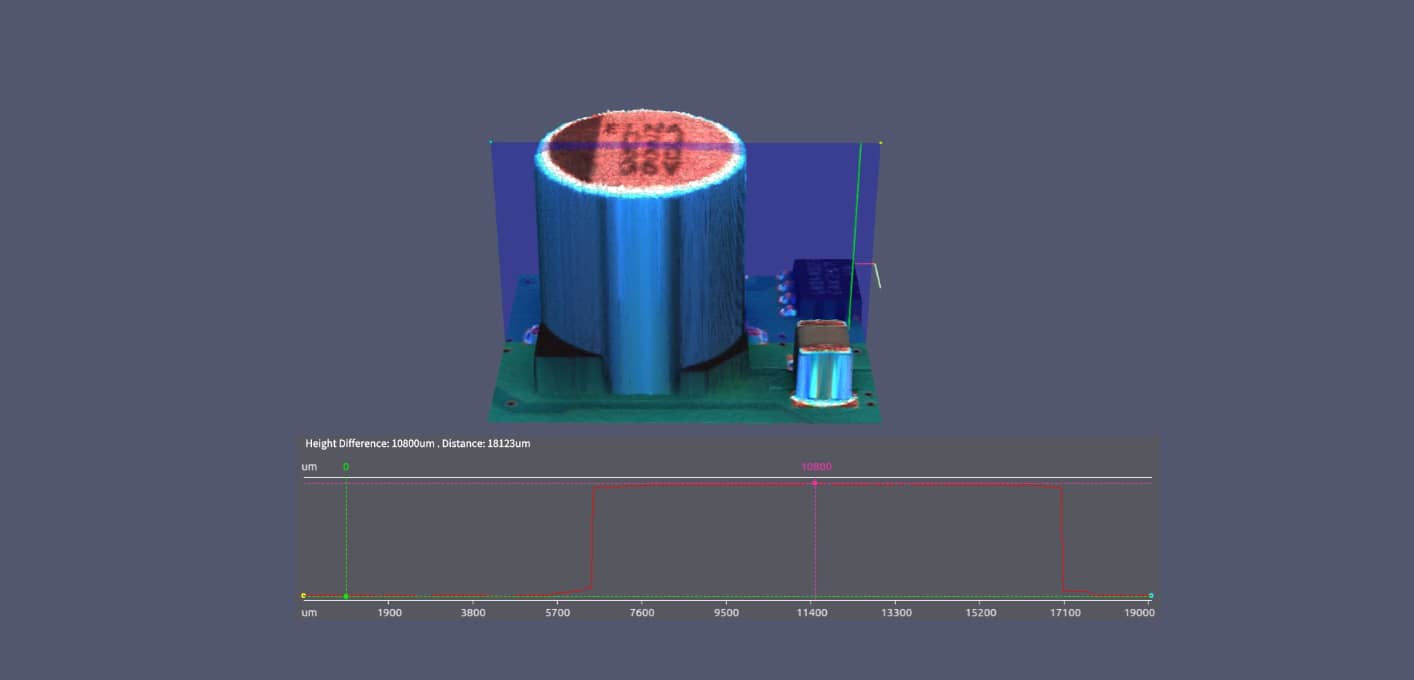

Real-time high-definition image capturing of tall and miniature components, improving the quality of silk screen imaging by adjusting the Z-axis height of specific devices with a specific FOV, and being compatible with up to 25mm device imaging.

Multi-directional projection and multi-frequency fringe patterns solve the problem of imaging overexposure, integrate AI denoising function, inspect object 3D image reconstruction, and provide accurate 3D data.

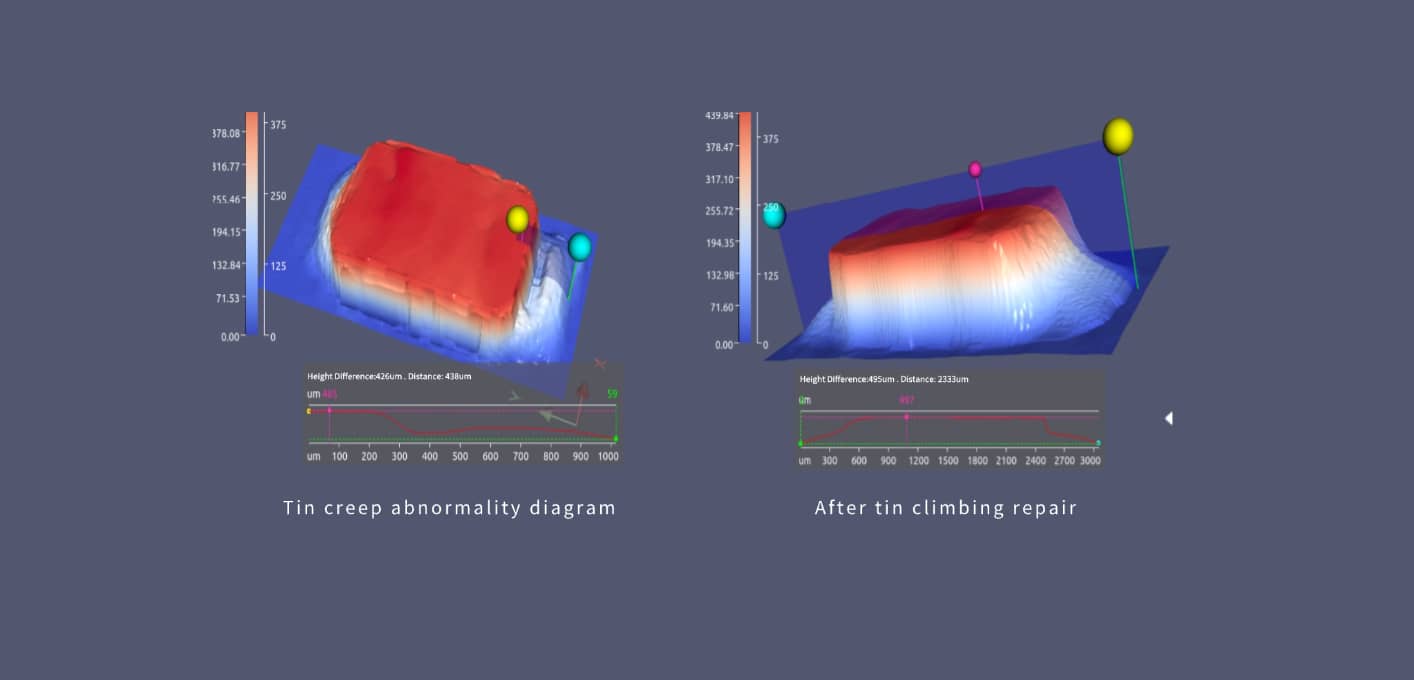

Based on the IPC standard, optimize the preset parameters of solder joint creep, reduce manual debugging steps, ensure program consistency, and effectively detect defects such as solder joint virtual soldering, insufficient solder, and excessive solder.

Identify the solder ball size and position of the entire board without manual pre-processing to eliminate noise from the silk screen.

Customers

They all chose MAKER-RAY